Щ…ЩҲШіШ№ Ш§Щ„ЩҒШұШ§Щ…Щ„: Щ…ЩғЩҲЩҶ ШЈШіШ§ШіЩҠ Щ„ШЈШҜШ§ШЎ ЩғШЁШӯ Щ…ЩҲШ«ЩҲЩӮ

Sep 19, 2025

Щ…ЩҲШіШ№ Ш§Щ„ЩҒШұШ§Щ…Щ„: Щ…ЩғЩҲЩҶ ШЈШіШ§ШіЩҠ Щ„ШЈШҜШ§ШЎ ЩғШЁШӯ Щ…ЩҲШ«ЩҲЩӮ

Ш§Щ„

Щ…ЩҲШіЩ‘Ш№ Ш§Щ„ЩҒШұШ§Щ…Щ„

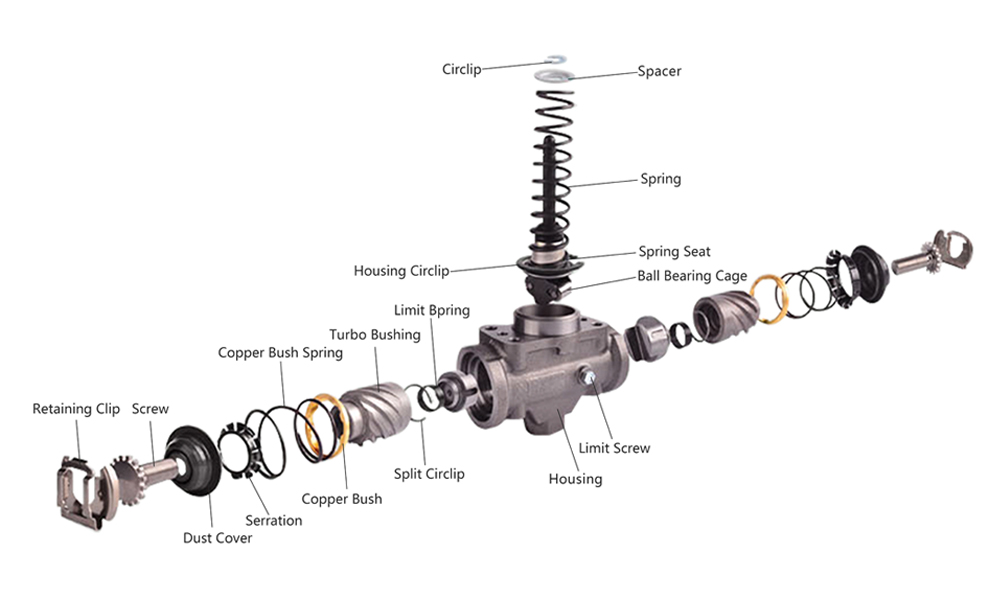

ЩҮЩҲ Щ…ЩғЩҲЩҶ ШЈШіШ§ШіЩҠ ЩҒЩҠ ЩҒШұШ§Щ…Щ„ Ш§Щ„ШЈШіШ·ЩҲШ§ЩҶШ©. ЩҠШ№ШӘЩ…ШҜ Щ…ШЁШҜШЈ Ш№Щ…Щ„ЩҮ ШЁШҙЩғЩ„ ШЈШіШ§ШіЩҠ Ш№Щ„Щү Ш§Щ„ШӘШҙШәЩҠЩ„ Ш§Щ„Щ…ЩҠЩғШ§ЩҶЩҠЩғЩҠ ШЈЩҲ Ш§Щ„ЩҮЩҠШҜШұЩҲЩ„ЩҠЩғЩҠ/Ш§Щ„ЩҮЩҲШ§ШҰЩҠШҢ Щ…Щ…Ш§ ЩҠШӨШҜЩҠ ШҘЩ„Щү ШӘЩ…ШҜШҜ ШЈШӯШ°ЩҠШ© Ш§Щ„ЩҒШұШ§Щ…Щ„ Щ„Щ„Ш®Ш§ШұШ¬ ЩҲЩ…Щ„Ш§Щ…ШіШӘЩҮШ§ Щ„Щ„Ш¬ШҜШ§Шұ Ш§Щ„ШҜШ§Ш®Щ„ЩҠ Щ„ШЈШіШ·ЩҲШ§ЩҶШ© Ш§Щ„ЩҒШұШ§Щ…Щ„ШҢ Щ…Щ…Ш§ ЩҠЩҸЩҲЩ„Щ‘ШҜ Ш§ШӯШӘЩғШ§ЩғЩӢШ§ШҢ ЩҲШЁШ§Щ„ШӘШ§Щ„ЩҠ ШӘШӯЩӮЩҠЩӮ Ш§Щ„ЩғШЁШӯ.

1. ШўЩ„ЩҠШ© Ш§Щ„Ш№Щ…Щ„ Ш§Щ„ШӘЩҒШөЩҠЩ„ЩҠШ© ЩҮЩҠ ЩғЩ…Ш§ ЩҠЩ„ЩҠ:

ШЈЩҲЩ„Ш§: Ш§Щ„ЩҮЩҠЩғЩ„ Ш§Щ„ШЈШіШ§ШіЩҠ

1. ШЈШӯШ°ЩҠШ© Ш§Щ„ЩҒШұШ§Щ…Щ„: ЩҠШӘЩ… ШӘШұЩғЩҠШЁЩҮШ§ ЩҒЩҠ ШЈШІЩҲШ§Ш¬ШҢ Щ…Ш№ ШЁШ·Ш§ЩҶШ§ШӘ Ш§ШӯШӘЩғШ§Щғ Щ…Ш«ШЁШӘШ© Ш№Щ„Щү ШіШ·ШӯЩҮШ§ Ш§Щ„Ш®Ш§ШұШ¬ЩҠШҢ ШЁШӯЩҠШ« ЩҠШӘШ·Ш§ШЁЩӮ ШҙЩғЩ„ЩҮШ§ Щ…Ш№ Ш§ЩҶШӯЩҶШ§ШЎ Ш§Щ„Ш¬ШҜШ§Шұ Ш§Щ„ШҜШ§Ш®Щ„ЩҠ Щ„ШЈШіШ·ЩҲШ§ЩҶШ© Ш§Щ„ЩҒШұШ§Щ…Щ„.

2. ШўЩ„ЩҠШ© Ш§Щ„ЩӮЩҠШ§ШҜШ©: ШӘШӘШ¶Щ…ЩҶ ШЈШіШ·ЩҲШ§ЩҶШ© Ш№Ш¬Щ„Ш© ЩҮЩҠШҜШұЩҲЩ„ЩҠЩғЩҠШ©ШҢ ШЈЩҲ Щ…ЩғШЁШі ЩҮЩҲШ§ШҰЩҠШҢ ШЈЩҲ ЩғШ§ШЁЩ„ Щ…ЩҠЩғШ§ЩҶЩҠЩғЩҠШҢ Ш§Щ„Щ…ШіШӨЩҲЩ„ Ш№ЩҶ ШҜЩҒШ№ ШЈШӯШ°ЩҠШ© Ш§Щ„ЩҒШұШ§Щ…Щ„ Щ„Щ„ШӘЩҲШіШ№.

3. ШІЩҶШЁШұЩғ Ш§Щ„ШҘШұШ¬Ш§Ш№: ЩҠШіШӯШЁ ШЈШӯШ°ЩҠШ© Ш§Щ„ЩҒШұШ§Щ…Щ„ ШҘЩ„Щү Щ…ЩҲШ¶Ш№ЩҮШ§ Щ…ШұШ© ШЈШ®ШұЩү Ш№ЩҶШҜ ШӘШӯШұЩҠШұ Ш§Щ„ЩҒШұШ§Щ…Щ„ШҢ Щ…Ш№ Ш§Щ„ШӯЩҒШ§Шё Ш№Щ„Щү Ш§Щ„Ш®Щ„ЩҲШө Ш§Щ„ШЈЩҲЩ„ЩҠ Щ…Ш№ ШЈШіШ·ЩҲШ§ЩҶШ© Ш§Щ„ЩҒШұШ§Щ…Щ„.

II. Ш§Щ„Ш№Щ…Щ„ЩҠШ© Ш§Щ„ШӘШҙШәЩҠЩ„ЩҠШ©

1. ШӘШҙШәЩҠЩ„ Ш§Щ„ЩҒШұШ§Щ…Щ„

Ш№ЩҶШҜЩ…Ш§ ЩҠШ¶ШәШ· Ш§Щ„ШіШ§ШҰЩӮ Ш№Щ„Щү ШҜЩҲШ§ШіШ© Ш§Щ„ЩҒШұШ§Щ…Щ„ШҢ ЩҠЩӮЩҲЩ… Ш§Щ„ЩҶШёШ§Щ… Ш§Щ„ЩҮЩҠШҜШұЩҲЩ„ЩҠЩғЩҠ/Ш§Щ„ЩҮЩҲШ§ШҰЩҠ ШЁШҜЩҒШ№ Щ…ЩғШЁШі ШЈШіШ·ЩҲШ§ЩҶШ© Ш§Щ„Ш№Ш¬Щ„Ш© ШЈЩҲ Ш§Щ„Щ…ЩғШЁШі Ш§Щ„ЩҮЩҲШ§ШҰЩҠ ШҘЩ„Щү Ш§Щ„Ш®Ш§ШұШ¬.

ЩҠШӘШіШЁШЁ Ш§Щ„Щ…ЩғШЁШіШҢ Щ…ЩҶ Ш®Щ„Ш§Щ„ ЩӮШ¶ЩҠШЁ Ш§Щ„ШӘЩҲШөЩҠЩ„ ШЈЩҲ ШўЩ„ЩҠШ© Ш§Щ„ЩғШ§Щ…ЩҠШұШ§ШҢ ЩҒЩҠ ШӘШЈШұШ¬Шӯ ШЈШӯШ°ЩҠШ© Ш§Щ„ЩҒШұШ§Щ…Щ„ Щ„Щ„Ш®Ш§ШұШ¬ ШӯЩҲЩ„ ЩҶЩӮШ·Ш© Щ…ШӯЩҲШұЩҠШ©ШҢ ЩҲШӘЩӮШӘШұШЁ ШӘШҜШұЩҠШ¬ЩҠЩӢШ§ Щ…ЩҶ Ш§Щ„Ш¬ШҜШ§Шұ Ш§Щ„ШҜШ§Ш®Щ„ЩҠ Щ„ШЈШіШ·ЩҲШ§ЩҶШ© Ш§Щ„ЩҒШұШ§Щ…Щ„.

2. Ш§Щ„ЩғШЁШӯ Ш§Щ„Ш§ШӯШӘЩғШ§ЩғЩҠ

Ш№ЩҶШҜЩ…Ш§ ЩҠЩ„Ш§Щ…Ші ШӯШ°Ш§ШЎ Ш§Щ„ЩҒШұШ§Щ…Щ„ ШЈШіШ·ЩҲШ§ЩҶШ© Ш§Щ„ЩҒШұШ§Щ…Щ„ Ш§Щ„ШҜЩҲШ§ШұШ©ШҢ ЩҠЩҲЩ„ШҜ Ш§Щ„Ш§ШӯШӘЩғШ§Щғ Ш№ШІЩ… Ш§Щ„ЩғШЁШӯШҢ Щ…Щ…Ш§ ЩҠШ¬ШЁШұ Ш§Щ„Ш№Ш¬Щ„Ш© Ш№Щ„Щү Ш§Щ„ШӘШЁШ§Ш·ШӨ.

ЩҒЩҠ ШӘШөЩ…ЩҠЩ… Ш§Щ„ШӯШ°Ш§ШЎ Ш§Щ„ШұШ§ШҰШҜ ЩҲШ§Щ„Ш®Щ„ЩҒЩҠШҢ ЩҠШ®Щ„ЩӮ Ш§Щ„ШӯШ°Ш§ШЎ Ш§Щ„ШұШ§ШҰШҜ "ШӘШЈШ«ЩҠШұ ШӘШ¶Ш®ЩҠЩ… Ш§Щ„ЩӮЩҲШ©" ШЁШіШЁШЁ Ш§ШӘШ¬Ш§ЩҮ Ш§Щ„ШҜЩҲШұШ§ЩҶШҢ Щ…Щ…Ш§ ЩҠШӨШҜЩҠ ШҘЩ„Щү Щ…ШІЩҠШҜ Щ…ЩҶ Ш§Щ„Ш¶ШәШ· Ш№Щ„Щү ШЈШіШ·ЩҲШ§ЩҶШ© Ш§Щ„ЩҒШұШ§Щ…Щ„.

3. ШӘШӯШұЩҠШұ Ш§Щ„ЩҒШұШ§Щ…Щ„

Ш№ЩҶШҜЩ…Ш§ ЩҠШӘЩ… ШӘШӯШұЩҠШұ Ш§Щ„ШҜЩҲШ§ШіШ©ШҢ ЩҠШ®ШӘЩҒЩҠ Ш§Щ„Ш¶ШәШ· Ш§Щ„Щ…ШӯШұЩғШҢ ЩҲЩҠШіШӯШЁ ШІЩҶШЁШұЩғ Ш§Щ„Ш№ЩҲШҜШ© ШӯШ°Ш§ШЎ Ш§Щ„ЩҒШұШ§Щ…Щ„ ШҘЩ„Щү Щ…ЩҲШ¶Ш№ЩҮ Щ…ШұШ© ШЈШ®ШұЩүШҢ ЩҲШӘЩҶЩҒШөЩ„ ШЁШ·Ш§ЩҶШ© Ш§Щ„Ш§ШӯШӘЩғШ§Щғ Ш№ЩҶ Ш§Щ„ШЈШіШ·ЩҲШ§ЩҶШ©.

Ш«Ш§Щ„Ш«ЩӢШ§: Ш§Щ„ШӘЩҒШ§ШөЩҠЩ„ Ш§Щ„ШұШҰЩҠШіЩҠШ©

Ш§Щ„ШӘШӯЩғЩ… ЩҒЩҠ Ш§Щ„Ш®Щ„ЩҲШө: Ш§Щ„Ш®Щ„ЩҲШө Ш§Щ„ШЈЩҲЩ„ЩҠ ЩҠЩғЩҲЩҶ Ш№Ш§ШҜШ© 0.2-0.5 Щ…Щ…ШҢ ЩҲШӘЩғЩҲЩҶ ЩҮЩҶШ§Щғ ШӯШ§Ш¬Ш© ШҘЩ„Щү ШўЩ„ЩҠШ© ШӘШ№ШҜЩҠЩ„ Щ„Щ„ШӘШ№ЩҲЩҠШ¶ Ш№ЩҶ Ш§Щ„ШӘШўЩғЩ„.

Щ…Ш§ШҜШ© Ш§Щ„Ш§ШӯШӘЩғШ§Щғ: ЩҠШ¬ШЁ ШЈЩҶ ШӘЩғЩҲЩҶ Щ…Ш§ШҜШ© Ш§Щ„ШЁШ·Ш§ЩҶШ© Щ…ЩӮШ§ЩҲЩ…Ш© Щ„Щ„ШӯШұШ§ШұШ© ЩҲШӘШӘЩ…ШӘШ№ ШЁЩ…Ш№Ш§Щ…Щ„ Ш§ШӯШӘЩғШ§Щғ Щ…ШұШӘЩҒШ№ Щ„Щ…ЩҶШ№ Ш§Щ„ШӘШӯЩ„Щ„ Ш§Щ„ШӯШұШ§ШұЩҠ.

ШұШ§ШЁШ№ЩӢШ§: Ш§Ш®ШӘЩ„Ш§ЩҒШ§ШӘ Ш§Щ„ЩҶЩҲШ№

Ш§Щ„ШӘШҙШәЩҠЩ„ Ш§Щ„ЩҮЩҠШҜШұЩҲЩ„ЩҠЩғЩҠ: ЩҠШіШӘШ®ШҜЩ… Ш№Ш§ШҜШ© ЩҒЩҠ ШіЩҠШ§ШұШ§ШӘ Ш§Щ„ШұЩғШ§ШЁШҢ ЩҲЩҠШіШӘШ®ШҜЩ… ШіШ§ШҰЩ„ Ш§Щ„ЩҒШұШ§Щ…Щ„ Щ„ЩҶЩӮЩ„ Ш§Щ„Ш¶ШәШ·.

Ш§Щ„ШӘШҙШәЩҠЩ„ Ш§Щ„ЩҮЩҲШ§ШҰЩҠ: ЩҠШіШӘШ®ШҜЩ… ЩҒЩҠ Ш§Щ„Щ…ШұЩғШЁШ§ШӘ Ш§Щ„Ш«ЩӮЩҠЩ„Ш© Щ…Ш«Щ„ Ш§Щ„ШҙШ§ШӯЩҶШ§ШӘШҢ ЩҲЩҠШ№ШӘЩ…ШҜ Ш№Щ„Щү Ш§Щ„ЩҮЩҲШ§ШЎ Ш§Щ„Щ…Ш¶ШәЩҲШ· Щ„ШҜЩҒШ№ Ш§Щ„Щ…ЩғШЁШі.

ЩҒЩҠ Ш§Щ„ШіЩҶЩҲШ§ШӘ Ш§Щ„ШЈШ®ЩҠШұШ©ШҢ ШЈШөШЁШӯ Ш§Щ„ШӯШөЩҲЩ„ Ш№Щ„Щү Ш§Щ„Щ…ЩҲШ§ШұШҜ Щ…ЩҶ

Щ…ШөЩҶШ№ Щ…ЩҲШіЩ‘Ш№ Ш§Щ„ЩҒШұШ§Щ…Щ„ ЩҒЩҠ Ш§Щ„ШөЩҠЩҶ

ШЈШөШЁШӯШӘ Ш®ЩҠШ§ШұЩӢШ§ Щ…ЩҒШ¶Щ„ЩӢШ§ Щ„Щ„Щ…ШҙШӘШұЩҠЩҶ Ш§Щ„Ш№Ш§Щ„Щ…ЩҠЩҠЩҶ. ШЁЩҒШ¶Щ„ Щ…Ш№ШҜШ§ШӘ Ш§Щ„ШҘЩҶШӘШ§Ш¬ Ш§Щ„Щ…ШӘШ·ЩҲШұШ©ШҢ ЩҲШ№Щ…Щ„ЩҠШ§ШӘ Ш§Щ„ШӘШөЩҶЩҠШ№ Ш§Щ„Щ…Ш№ШӘЩ…ШҜШ© Щ…ЩҶ IATF16949ШҢ ЩҲШ§Щ„ШЈШіШ№Ш§Шұ Ш§Щ„ШӘЩҶШ§ЩҒШіЩҠШ©ШҢ ЩҠЩӮШҜЩ… Ш§Щ„Щ…ЩҲШұШҜЩҲЩҶ Ш§Щ„ШөЩҠЩҶЩҠЩҲЩҶ Щ…ЩҲШіШ№Ш§ШӘ ЩҒШұШ§Щ…Щ„ Ш№Ш§Щ„ЩҠШ© Ш§Щ„Ш¬ЩҲШҜШ© ШӘЩҶШ§ШіШЁ Щ…Ш®ШӘЩ„ЩҒ Ш§Щ„ШЈШіЩҲШ§ЩӮ Ш§Щ„Ш№Ш§Щ„Щ…ЩҠШ©ШҢ Щ…Ш«Щ„ KOMP.

ШЈЩғШ«Шұ Щ…ЩҶ 20 Ш№Ш§Щ…ЩӢШ§ Щ…ЩҶ Ш§Щ„Ш®ШЁШұШ© ЩҒЩҠ ШҘЩҶШӘШ§Ш¬ Щ…ЩғЩҲЩҶШ§ШӘ ЩҶШёШ§Щ… Ш§Щ„ЩҒШұШ§Щ…Щ„.

Щ…Ш¬Щ…ЩҲШ№Ш© ЩҲШ§ШіШ№Ш© Щ…ЩҶ Ш§Щ„Щ…ЩҶШӘШ¬Ш§ШӘ ШӘШҙЩ…Щ„ ШЈШіШ·ЩҲШ§ЩҶШ§ШӘ Ш§Щ„ЩҒШұШ§Щ…Щ„ Ш§Щ„ШұШҰЩҠШіЩҠШ©ШҢ ЩҲШ§Щ„ШЈШіШ·ЩҲШ§ЩҶШ§ШӘ Ш§Щ„Щ…ШіШ§Ш№ШҜШ©ШҢ ЩҲШ§Щ„Щ…ЩҲШіШ№Ш§ШӘ. Ш¶Щ…Ш§ЩҶ Щ„Щ…ШҜШ© Ш№Ш§Щ… ШЈЩҲ 30,000 ЩғЩ… Щ„Ш¶Щ…Ш§ЩҶ ШұШ¶Ш§ Ш§Щ„Ш№Щ…ЩҠЩ„.

Ш№ЩҶ Ш·ШұЩҠЩӮ Ш§Ш®ШӘЩҠШ§Шұ Щ…ЩҲШ«ЩҲЩӮ ШЁЩҮШ§

Щ…ЩҸШөЩҶЩҗЩ‘Ш№ Щ…ЩҲШіЩҗЩ‘Ш№ Ш§Щ„ЩҒШұШ§Щ…Щ„

ШҢ ЩҒШЈЩҶШӘ Щ„Ш§ ШӘШ№Щ…Щ„ Ш№Щ„Щү ШӘШӯШіЩҠЩҶ ШЈШҜШ§ШЎ Ш§Щ„ШіЩҠШ§ШұШ© ЩҒШӯШіШЁШҢ ШЁЩ„ ШӘШ¶Щ…ЩҶ ШЈЩҠШ¶ЩӢШ§ Ш§Щ„ШіЩ„Ш§Щ…Ш© Ш№Щ„Щү Ш§Щ„Щ…ШҜЩү Ш§Щ„Ш·ЩҲЩҠЩ„ ЩҲШ§Щ„ЩҒШ№Ш§Щ„ЩҠШ© Щ…ЩҶ ШӯЩҠШ« Ш§Щ„ШӘЩғЩ„ЩҒШ© Щ„ШЈШіШ·ЩҲЩ„Щғ ШЈЩҲ ШЈШ№Щ…Ш§Щ„ Ш§Щ„ШӘЩҲШІЩҠШ№.

1. ШўЩ„ЩҠШ© Ш§Щ„Ш№Щ…Щ„ Ш§Щ„ШӘЩҒШөЩҠЩ„ЩҠШ© ЩҮЩҠ ЩғЩ…Ш§ ЩҠЩ„ЩҠ:

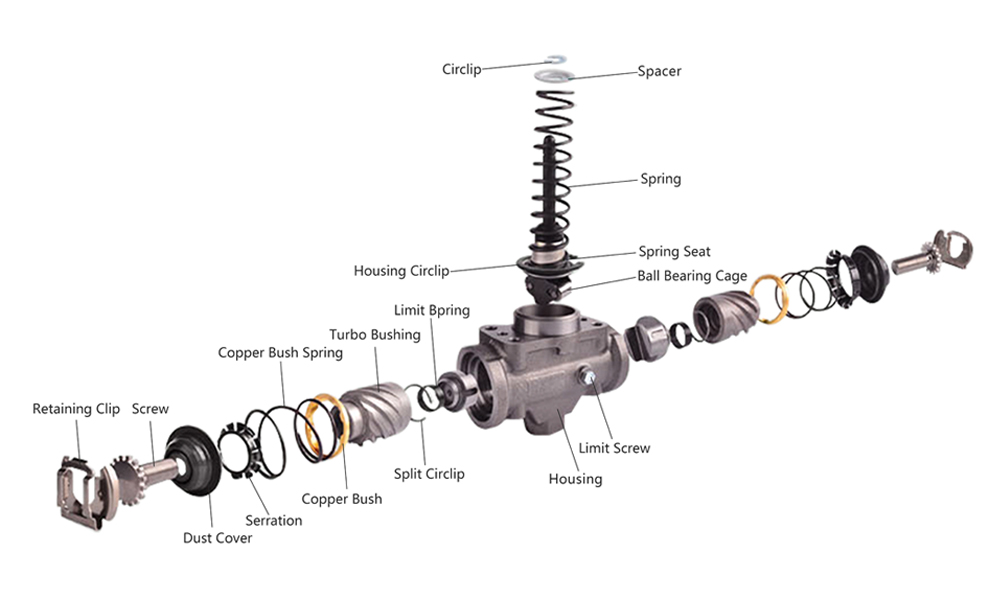

ШЈЩҲЩ„Ш§: Ш§Щ„ЩҮЩҠЩғЩ„ Ш§Щ„ШЈШіШ§ШіЩҠ

1. ШЈШӯШ°ЩҠШ© Ш§Щ„ЩҒШұШ§Щ…Щ„: ЩҠШӘЩ… ШӘШұЩғЩҠШЁЩҮШ§ ЩҒЩҠ ШЈШІЩҲШ§Ш¬ШҢ Щ…Ш№ ШЁШ·Ш§ЩҶШ§ШӘ Ш§ШӯШӘЩғШ§Щғ Щ…Ш«ШЁШӘШ© Ш№Щ„Щү ШіШ·ШӯЩҮШ§ Ш§Щ„Ш®Ш§ШұШ¬ЩҠШҢ ШЁШӯЩҠШ« ЩҠШӘШ·Ш§ШЁЩӮ ШҙЩғЩ„ЩҮШ§ Щ…Ш№ Ш§ЩҶШӯЩҶШ§ШЎ Ш§Щ„Ш¬ШҜШ§Шұ Ш§Щ„ШҜШ§Ш®Щ„ЩҠ Щ„ШЈШіШ·ЩҲШ§ЩҶШ© Ш§Щ„ЩҒШұШ§Щ…Щ„.

2. ШўЩ„ЩҠШ© Ш§Щ„ЩӮЩҠШ§ШҜШ©: ШӘШӘШ¶Щ…ЩҶ ШЈШіШ·ЩҲШ§ЩҶШ© Ш№Ш¬Щ„Ш© ЩҮЩҠШҜШұЩҲЩ„ЩҠЩғЩҠШ©ШҢ ШЈЩҲ Щ…ЩғШЁШі ЩҮЩҲШ§ШҰЩҠШҢ ШЈЩҲ ЩғШ§ШЁЩ„ Щ…ЩҠЩғШ§ЩҶЩҠЩғЩҠШҢ Ш§Щ„Щ…ШіШӨЩҲЩ„ Ш№ЩҶ ШҜЩҒШ№ ШЈШӯШ°ЩҠШ© Ш§Щ„ЩҒШұШ§Щ…Щ„ Щ„Щ„ШӘЩҲШіШ№.

3. ШІЩҶШЁШұЩғ Ш§Щ„ШҘШұШ¬Ш§Ш№: ЩҠШіШӯШЁ ШЈШӯШ°ЩҠШ© Ш§Щ„ЩҒШұШ§Щ…Щ„ ШҘЩ„Щү Щ…ЩҲШ¶Ш№ЩҮШ§ Щ…ШұШ© ШЈШ®ШұЩү Ш№ЩҶШҜ ШӘШӯШұЩҠШұ Ш§Щ„ЩҒШұШ§Щ…Щ„ШҢ Щ…Ш№ Ш§Щ„ШӯЩҒШ§Шё Ш№Щ„Щү Ш§Щ„Ш®Щ„ЩҲШө Ш§Щ„ШЈЩҲЩ„ЩҠ Щ…Ш№ ШЈШіШ·ЩҲШ§ЩҶШ© Ш§Щ„ЩҒШұШ§Щ…Щ„.

II. Ш§Щ„Ш№Щ…Щ„ЩҠШ© Ш§Щ„ШӘШҙШәЩҠЩ„ЩҠШ©

1. ШӘШҙШәЩҠЩ„ Ш§Щ„ЩҒШұШ§Щ…Щ„

Ш№ЩҶШҜЩ…Ш§ ЩҠШ¶ШәШ· Ш§Щ„ШіШ§ШҰЩӮ Ш№Щ„Щү ШҜЩҲШ§ШіШ© Ш§Щ„ЩҒШұШ§Щ…Щ„ШҢ ЩҠЩӮЩҲЩ… Ш§Щ„ЩҶШёШ§Щ… Ш§Щ„ЩҮЩҠШҜШұЩҲЩ„ЩҠЩғЩҠ/Ш§Щ„ЩҮЩҲШ§ШҰЩҠ ШЁШҜЩҒШ№ Щ…ЩғШЁШі ШЈШіШ·ЩҲШ§ЩҶШ© Ш§Щ„Ш№Ш¬Щ„Ш© ШЈЩҲ Ш§Щ„Щ…ЩғШЁШі Ш§Щ„ЩҮЩҲШ§ШҰЩҠ ШҘЩ„Щү Ш§Щ„Ш®Ш§ШұШ¬.

ЩҠШӘШіШЁШЁ Ш§Щ„Щ…ЩғШЁШіШҢ Щ…ЩҶ Ш®Щ„Ш§Щ„ ЩӮШ¶ЩҠШЁ Ш§Щ„ШӘЩҲШөЩҠЩ„ ШЈЩҲ ШўЩ„ЩҠШ© Ш§Щ„ЩғШ§Щ…ЩҠШұШ§ШҢ ЩҒЩҠ ШӘШЈШұШ¬Шӯ ШЈШӯШ°ЩҠШ© Ш§Щ„ЩҒШұШ§Щ…Щ„ Щ„Щ„Ш®Ш§ШұШ¬ ШӯЩҲЩ„ ЩҶЩӮШ·Ш© Щ…ШӯЩҲШұЩҠШ©ШҢ ЩҲШӘЩӮШӘШұШЁ ШӘШҜШұЩҠШ¬ЩҠЩӢШ§ Щ…ЩҶ Ш§Щ„Ш¬ШҜШ§Шұ Ш§Щ„ШҜШ§Ш®Щ„ЩҠ Щ„ШЈШіШ·ЩҲШ§ЩҶШ© Ш§Щ„ЩҒШұШ§Щ…Щ„.

2. Ш§Щ„ЩғШЁШӯ Ш§Щ„Ш§ШӯШӘЩғШ§ЩғЩҠ

Ш№ЩҶШҜЩ…Ш§ ЩҠЩ„Ш§Щ…Ші ШӯШ°Ш§ШЎ Ш§Щ„ЩҒШұШ§Щ…Щ„ ШЈШіШ·ЩҲШ§ЩҶШ© Ш§Щ„ЩҒШұШ§Щ…Щ„ Ш§Щ„ШҜЩҲШ§ШұШ©ШҢ ЩҠЩҲЩ„ШҜ Ш§Щ„Ш§ШӯШӘЩғШ§Щғ Ш№ШІЩ… Ш§Щ„ЩғШЁШӯШҢ Щ…Щ…Ш§ ЩҠШ¬ШЁШұ Ш§Щ„Ш№Ш¬Щ„Ш© Ш№Щ„Щү Ш§Щ„ШӘШЁШ§Ш·ШӨ.

ЩҒЩҠ ШӘШөЩ…ЩҠЩ… Ш§Щ„ШӯШ°Ш§ШЎ Ш§Щ„ШұШ§ШҰШҜ ЩҲШ§Щ„Ш®Щ„ЩҒЩҠШҢ ЩҠШ®Щ„ЩӮ Ш§Щ„ШӯШ°Ш§ШЎ Ш§Щ„ШұШ§ШҰШҜ "ШӘШЈШ«ЩҠШұ ШӘШ¶Ш®ЩҠЩ… Ш§Щ„ЩӮЩҲШ©" ШЁШіШЁШЁ Ш§ШӘШ¬Ш§ЩҮ Ш§Щ„ШҜЩҲШұШ§ЩҶШҢ Щ…Щ…Ш§ ЩҠШӨШҜЩҠ ШҘЩ„Щү Щ…ШІЩҠШҜ Щ…ЩҶ Ш§Щ„Ш¶ШәШ· Ш№Щ„Щү ШЈШіШ·ЩҲШ§ЩҶШ© Ш§Щ„ЩҒШұШ§Щ…Щ„.

3. ШӘШӯШұЩҠШұ Ш§Щ„ЩҒШұШ§Щ…Щ„

Ш№ЩҶШҜЩ…Ш§ ЩҠШӘЩ… ШӘШӯШұЩҠШұ Ш§Щ„ШҜЩҲШ§ШіШ©ШҢ ЩҠШ®ШӘЩҒЩҠ Ш§Щ„Ш¶ШәШ· Ш§Щ„Щ…ШӯШұЩғШҢ ЩҲЩҠШіШӯШЁ ШІЩҶШЁШұЩғ Ш§Щ„Ш№ЩҲШҜШ© ШӯШ°Ш§ШЎ Ш§Щ„ЩҒШұШ§Щ…Щ„ ШҘЩ„Щү Щ…ЩҲШ¶Ш№ЩҮ Щ…ШұШ© ШЈШ®ШұЩүШҢ ЩҲШӘЩҶЩҒШөЩ„ ШЁШ·Ш§ЩҶШ© Ш§Щ„Ш§ШӯШӘЩғШ§Щғ Ш№ЩҶ Ш§Щ„ШЈШіШ·ЩҲШ§ЩҶШ©.

Ш«Ш§Щ„Ш«ЩӢШ§: Ш§Щ„ШӘЩҒШ§ШөЩҠЩ„ Ш§Щ„ШұШҰЩҠШіЩҠШ©

Ш§Щ„ШӘШӯЩғЩ… ЩҒЩҠ Ш§Щ„Ш®Щ„ЩҲШө: Ш§Щ„Ш®Щ„ЩҲШө Ш§Щ„ШЈЩҲЩ„ЩҠ ЩҠЩғЩҲЩҶ Ш№Ш§ШҜШ© 0.2-0.5 Щ…Щ…ШҢ ЩҲШӘЩғЩҲЩҶ ЩҮЩҶШ§Щғ ШӯШ§Ш¬Ш© ШҘЩ„Щү ШўЩ„ЩҠШ© ШӘШ№ШҜЩҠЩ„ Щ„Щ„ШӘШ№ЩҲЩҠШ¶ Ш№ЩҶ Ш§Щ„ШӘШўЩғЩ„.

Щ…Ш§ШҜШ© Ш§Щ„Ш§ШӯШӘЩғШ§Щғ: ЩҠШ¬ШЁ ШЈЩҶ ШӘЩғЩҲЩҶ Щ…Ш§ШҜШ© Ш§Щ„ШЁШ·Ш§ЩҶШ© Щ…ЩӮШ§ЩҲЩ…Ш© Щ„Щ„ШӯШұШ§ШұШ© ЩҲШӘШӘЩ…ШӘШ№ ШЁЩ…Ш№Ш§Щ…Щ„ Ш§ШӯШӘЩғШ§Щғ Щ…ШұШӘЩҒШ№ Щ„Щ…ЩҶШ№ Ш§Щ„ШӘШӯЩ„Щ„ Ш§Щ„ШӯШұШ§ШұЩҠ.

ШұШ§ШЁШ№ЩӢШ§: Ш§Ш®ШӘЩ„Ш§ЩҒШ§ШӘ Ш§Щ„ЩҶЩҲШ№

Ш§Щ„ШӘШҙШәЩҠЩ„ Ш§Щ„ЩҮЩҠШҜШұЩҲЩ„ЩҠЩғЩҠ: ЩҠШіШӘШ®ШҜЩ… Ш№Ш§ШҜШ© ЩҒЩҠ ШіЩҠШ§ШұШ§ШӘ Ш§Щ„ШұЩғШ§ШЁШҢ ЩҲЩҠШіШӘШ®ШҜЩ… ШіШ§ШҰЩ„ Ш§Щ„ЩҒШұШ§Щ…Щ„ Щ„ЩҶЩӮЩ„ Ш§Щ„Ш¶ШәШ·.

Ш§Щ„ШӘШҙШәЩҠЩ„ Ш§Щ„ЩҮЩҲШ§ШҰЩҠ: ЩҠШіШӘШ®ШҜЩ… ЩҒЩҠ Ш§Щ„Щ…ШұЩғШЁШ§ШӘ Ш§Щ„Ш«ЩӮЩҠЩ„Ш© Щ…Ш«Щ„ Ш§Щ„ШҙШ§ШӯЩҶШ§ШӘШҢ ЩҲЩҠШ№ШӘЩ…ШҜ Ш№Щ„Щү Ш§Щ„ЩҮЩҲШ§ШЎ Ш§Щ„Щ…Ш¶ШәЩҲШ· Щ„ШҜЩҒШ№ Ш§Щ„Щ…ЩғШЁШі.

ЩҒЩҠ Ш§Щ„ШіЩҶЩҲШ§ШӘ Ш§Щ„ШЈШ®ЩҠШұШ©ШҢ ШЈШөШЁШӯ Ш§Щ„ШӯШөЩҲЩ„ Ш№Щ„Щү Ш§Щ„Щ…ЩҲШ§ШұШҜ Щ…ЩҶ

Щ…ШөЩҶШ№ Щ…ЩҲШіЩ‘Ш№ Ш§Щ„ЩҒШұШ§Щ…Щ„ ЩҒЩҠ Ш§Щ„ШөЩҠЩҶ

ШЈШөШЁШӯШӘ Ш®ЩҠШ§ШұЩӢШ§ Щ…ЩҒШ¶Щ„ЩӢШ§ Щ„Щ„Щ…ШҙШӘШұЩҠЩҶ Ш§Щ„Ш№Ш§Щ„Щ…ЩҠЩҠЩҶ. ШЁЩҒШ¶Щ„ Щ…Ш№ШҜШ§ШӘ Ш§Щ„ШҘЩҶШӘШ§Ш¬ Ш§Щ„Щ…ШӘШ·ЩҲШұШ©ШҢ ЩҲШ№Щ…Щ„ЩҠШ§ШӘ Ш§Щ„ШӘШөЩҶЩҠШ№ Ш§Щ„Щ…Ш№ШӘЩ…ШҜШ© Щ…ЩҶ IATF16949ШҢ ЩҲШ§Щ„ШЈШіШ№Ш§Шұ Ш§Щ„ШӘЩҶШ§ЩҒШіЩҠШ©ШҢ ЩҠЩӮШҜЩ… Ш§Щ„Щ…ЩҲШұШҜЩҲЩҶ Ш§Щ„ШөЩҠЩҶЩҠЩҲЩҶ Щ…ЩҲШіШ№Ш§ШӘ ЩҒШұШ§Щ…Щ„ Ш№Ш§Щ„ЩҠШ© Ш§Щ„Ш¬ЩҲШҜШ© ШӘЩҶШ§ШіШЁ Щ…Ш®ШӘЩ„ЩҒ Ш§Щ„ШЈШіЩҲШ§ЩӮ Ш§Щ„Ш№Ш§Щ„Щ…ЩҠШ©ШҢ Щ…Ш«Щ„ KOMP.

ШЈЩғШ«Шұ Щ…ЩҶ 20 Ш№Ш§Щ…ЩӢШ§ Щ…ЩҶ Ш§Щ„Ш®ШЁШұШ© ЩҒЩҠ ШҘЩҶШӘШ§Ш¬ Щ…ЩғЩҲЩҶШ§ШӘ ЩҶШёШ§Щ… Ш§Щ„ЩҒШұШ§Щ…Щ„.

Щ…Ш¬Щ…ЩҲШ№Ш© ЩҲШ§ШіШ№Ш© Щ…ЩҶ Ш§Щ„Щ…ЩҶШӘШ¬Ш§ШӘ ШӘШҙЩ…Щ„ ШЈШіШ·ЩҲШ§ЩҶШ§ШӘ Ш§Щ„ЩҒШұШ§Щ…Щ„ Ш§Щ„ШұШҰЩҠШіЩҠШ©ШҢ ЩҲШ§Щ„ШЈШіШ·ЩҲШ§ЩҶШ§ШӘ Ш§Щ„Щ…ШіШ§Ш№ШҜШ©ШҢ ЩҲШ§Щ„Щ…ЩҲШіШ№Ш§ШӘ. Ш¶Щ…Ш§ЩҶ Щ„Щ…ШҜШ© Ш№Ш§Щ… ШЈЩҲ 30,000 ЩғЩ… Щ„Ш¶Щ…Ш§ЩҶ ШұШ¶Ш§ Ш§Щ„Ш№Щ…ЩҠЩ„.

Ш№ЩҶ Ш·ШұЩҠЩӮ Ш§Ш®ШӘЩҠШ§Шұ Щ…ЩҲШ«ЩҲЩӮ ШЁЩҮШ§

Щ…ЩҸШөЩҶЩҗЩ‘Ш№ Щ…ЩҲШіЩҗЩ‘Ш№ Ш§Щ„ЩҒШұШ§Щ…Щ„

ШҢ ЩҒШЈЩҶШӘ Щ„Ш§ ШӘШ№Щ…Щ„ Ш№Щ„Щү ШӘШӯШіЩҠЩҶ ШЈШҜШ§ШЎ Ш§Щ„ШіЩҠШ§ШұШ© ЩҒШӯШіШЁШҢ ШЁЩ„ ШӘШ¶Щ…ЩҶ ШЈЩҠШ¶ЩӢШ§ Ш§Щ„ШіЩ„Ш§Щ…Ш© Ш№Щ„Щү Ш§Щ„Щ…ШҜЩү Ш§Щ„Ш·ЩҲЩҠЩ„ ЩҲШ§Щ„ЩҒШ№Ш§Щ„ЩҠШ© Щ…ЩҶ ШӯЩҠШ« Ш§Щ„ШӘЩғЩ„ЩҒШ© Щ„ШЈШіШ·ЩҲЩ„Щғ ШЈЩҲ ШЈШ№Щ…Ш§Щ„ Ш§Щ„ШӘЩҲШІЩҠШ№.